Plant Maintenance Division

Fully equipped 29.80m x 33.60m CNC workshop, located in the Jebal Ali free zone, Dubai. Incorporating new state of the art Mega Slant and Mega Turn Heavy duty, CNC lathes and Horizontal Boring machine.

2x SA 45 (Dugard) 3200mm Turn mills

1x SA 45 (Dugard) 5200mm Turn mills

1x (Youji) HBM CNC Horizontal borer

The HBM, with Rotary table, using the latest hydrostatic technology and can carry a maximum of 20 tons in conjunction with a floor type ATC (Automatic Tool Changer) 60 tool holders and therefore the ATC system does not interfere with the machining accuracy. A high precision “B” axis, provides positioning and repeatability accuracy. The combination of both the 3-axis and Baxis allows four-axis-machining, a capability which provides all of the necessary criteria for critical machining needs of complex geometry work pieces.

SUPPLY OF 2 RISER STACK PACKAGES FOR KNPC CLEAN FUEL PROJECT-KUWAIT

CLIENT

JOHN ZINK HAMWORTHY COMBUSTION / PETROFAC / SAMSUNG / KNPC

SCOPE:

PRODUCT RANGE

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, TESTING, 2D TRIAL ASSEMBLY, PAINTING, GALVANIZING, PACKING, LOADING

HEIGHT:- 140 MTR

DIA METER:- 32 ” (812 MM)

WEIGHT:- 58 & 216 TON

EXECUTION TIME PERIOD:

8 MONTHS

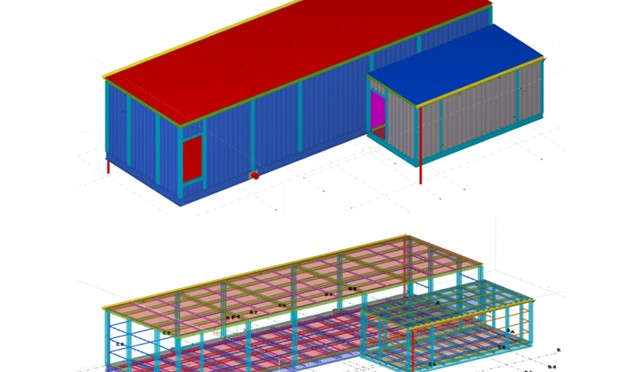

PEB, STRUCTURAL STEEL FOR EMAL SMELTER PROJECT, PHASE 2, ABU DHABI

CLIENT

NKM NOELL GmbH – GERMANY / SNC Lavalin International

SCOPE:

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, PRE ASSEMBLY, GALVANIZING PAINTING, EX – WORKS TOTAL : 650 TONS

EXECUTION TIME PERIOD:

5 WEEKS

SUPPLY OF 2 DERRICK PACKAGES FOR KNPC CLEAN FUEL PROJECT-KUWAIT

CLIENT

JOHN ZINK HAMWORTHY COMBUSTION / PETROFAC / SAMSUNG / KNPC

SCOPE:

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, TESTING, 2D TRIAL ASSEMBLY, PAINTING, GALVANIZING, PACKING, LOADING

HEIGHT:- 130 MTR

WIDTH FROM BOTTOM:- 20 MTR CENTER TO CENTER

WIDTH FROM TOP:- 8 MTR CENTER TO CENTER

WEIGHT:- 280 & 308 TON

EXECUTION TIME PERIOD:

6 MONTHS

SUPPLY OF 6 NO. STACKS FOR STEAM BOILERS FOR KNPC MAB-2 CLEAN FUEL PROJECT 2020, KUWAIT

CLIENT

SOFINTER MACCHI / KNPC

SCOPE:

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, TESTING, PRE-ASSEMBLY, PAINTING, GALVANIZING, PACKING & LOADING STACKS, SERVICES PLATFORMS & LADDERS

EXECUTION TIME PERIOD:

4 MONTHS

25 NO. FIELD ERECTED FLOATING ROOF & FIXED CONE ROOF STORAGE TANKS FOR GC-31 PROJECT, KUWAIT

CLIENT

DODSAL / AMEC FOSTER WHEELER / WORLEY PARSONS / KOC

SCOPE:

DESIGN, DETAILED ENGINEERING, PRE-FABRICATION, SITE ERECTION, PAINTING

HEIGHT:- UP TO 17 MTR

DIA METER:- UP TO 50 MTR

EXECUTION TIME PERIOD:

18 MONTHS

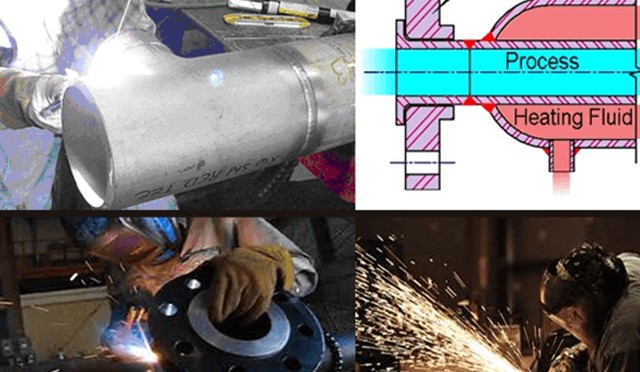

150 SPOOLS OF JACKETED PIPING FOR TRAIN-1 & TRAIN-2, ADGAS DAS ISLAND, UAE

CLIENT

QCON / ADGAS

SCOPE:

DETAILED ENGINEERING,

MATERIAL PROCUREMENT,

FABRICATION,

TESTING,

PAINTING

EXECUTION TIME PERIOD:

3 MONTHS

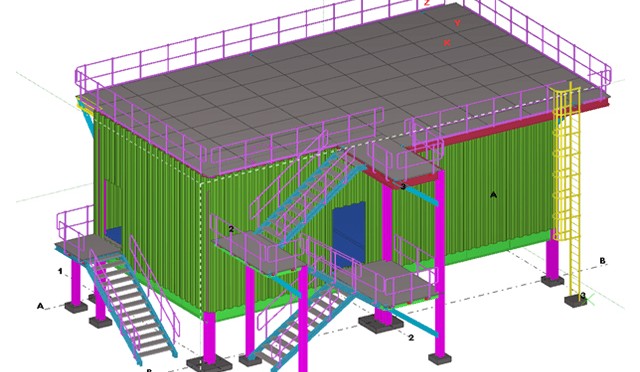

CICPA DATA BUILDINGS FOR ZADCO PROJECT

CLIENT

PETROFAC / ZADCO

SCOPE:

DESIGN & DETAILED ENGINEERING,

MATERIAL PROCUREMENT, FABRICATION,

TESTING, ASSEMBLY,

PAINTING,

INSULATION, ELECTRICAL & ENI.

EXECUTION TIME PERIOD:

15 MONTHS

FILTERATION SKIDS FOR UPPER ZAKUM 750 ISLANDS SURFACE FACILITIES PROJECT – EPC2 PROJECT No: P7512

CLIENT

FAUDI FILTERATION / PETROFAC / ZADCO

SCOPE:

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, TESTING, ASSEMBLY, PAINTING, INSULATION, ELECTRICAL & FAT.

WEIGHT : 120 TON

LENGTH: 11 M

HEIGHT: 5 M

WIDTH: 5 M

EXECUTION TIME PERIOD:

4 MONTHS

Containers PO_RUMAITHA SHANAYEL Ph-3 DEV. Project

CLIENT

Tozzi Sud GS E&C

SCOPE:

DESIGN & DETAILED ENGINEERING,

MATERIAL PROCUREMENT, FABRICATION,

TESTING, ASSEMBLY,

PAINTING,

INSULATION, ELECTRICAL & FAT.

TRANSCO CONTAINER – 13960 KGS,

ADCO+BATTERY CONTAINER – 34868 KGS

220KV GIS FEEDER 1 – 12013 KGS,

220KV GIS FEEDER 2 – 12013 KGS

EXECUTION TIME PERIOD:

4 MONTHS

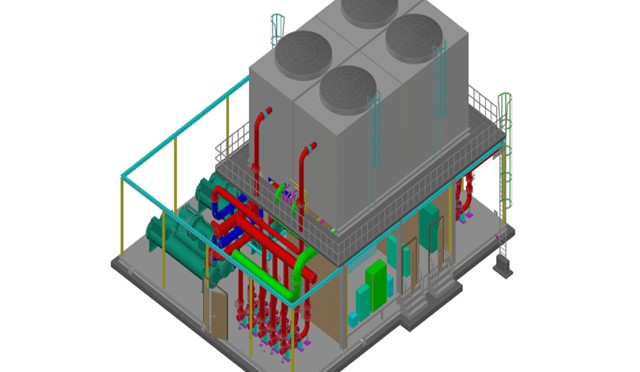

Rehabilitation of Central AC System Project King FAHD Hospital, Jizan, KSA

CLIENT

Stellar energy

SCOPE:

DETAILED ENGINEERING,

MATERIAL PROCUREMENT, FABRICATION,

TESTING, ASSEMBLY,

PAINTING,

INSULATION, ELECTRICAL & FAT.

EXECUTION TIME PERIOD:

4 MONTHS

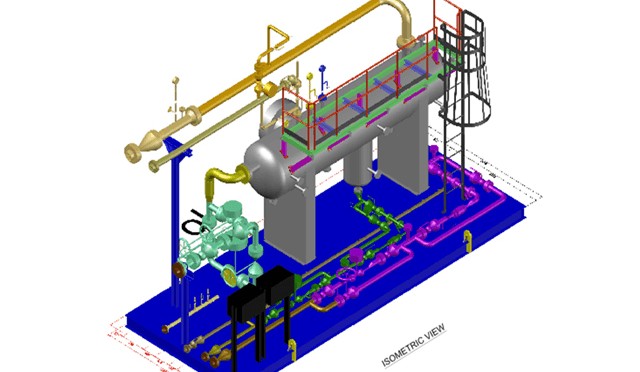

THREE PHASE SEPERATOR PACKAGE

CLIENT

Chartered Engineering & Outsourcing / Pakistan Petroleum Limited

SCOPE:

DESIGN & DETAILED ENGINEERING,

MATERIAL PROCUREMENT, FABRICATION,

TESTING, ASSEMBLY,

PAINTING,

INSULATION, ELECTRICAL & FAT

EXECUTION TIME PERIOD:

4 MONTHS

UPPER ZAKUM 750 ISLANDS SURFACE FACILITIES PROJECT – EPC2 PROJECT No: P7512

CLIENT

Faudi Filtrations Technologiee / Petrofac

SCOPE:

DETAILED ENGINEERING,

MATERIAL PROCUREMENT, FABRICATION,

TESTING, ASSEMBLY,

PAINTING,

INSULATION, ELECTRICAL & FAT.

WEIGHT : – 120 TON

L 11 MTR X 5175 H X 5020 W

EXECUTION TIME PERIOD:

4 MONTHS

FIREPROOF PAINTING BY INTUMESCENT PAINTING PITT-CHAR XP , ( PPG PAINTS) AT ZUBAIR OILFIELD PROJECT – IRAQ

CLIENT

WEATHERFORD

SCOPE:

TOTAL AREA – 15, 000 SQ MTRS

EXECUTION TIME PERIOD:

4 MONTHS

RIGS REFURBISHMENT-DISCOVERER-II

CLIENT

ATLANTIC MARINE SERVICE (CYPRUS)

SCOPE:

MATERIAL PROCUREMENT, FABRICATION,

TESTING,

ASSEMBLY AND PAINTING

AND CERTIFICATION

QTY :1 NO

EXECUTION TIME PERIOD:

5 MONTHS

STAINLESS STEEL PIPING FOR ZUBAIR HAMMAR, RAFIDIYA DEVELOPMENT PROJECT – IRAQ

CLIENT

WEATHERFORD

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING,

ASSEMBLY AND PAINTING

TOTAL QTY : 600 TONS

EXECUTION TIME PERIOD:

9 MONTHS

PROCESS PIPING FOR HAMAMR OILD FIELD PROJECT, IRAQ

CLIENT

WEATHERFORD

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING,

ASSEMBLY AND PAINTING

TOTAL QTY IN TONS : 8500 TONS

EXECUTION TIME PERIOD:

11 MONTHS

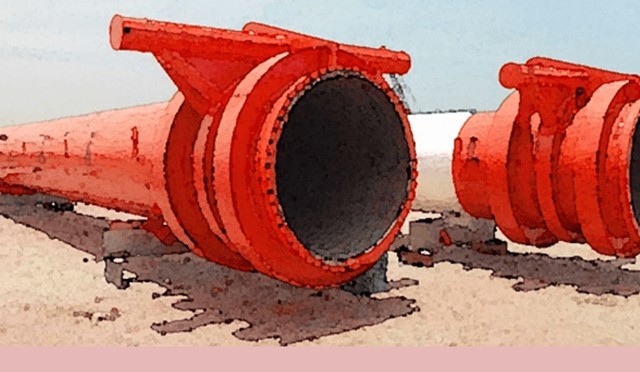

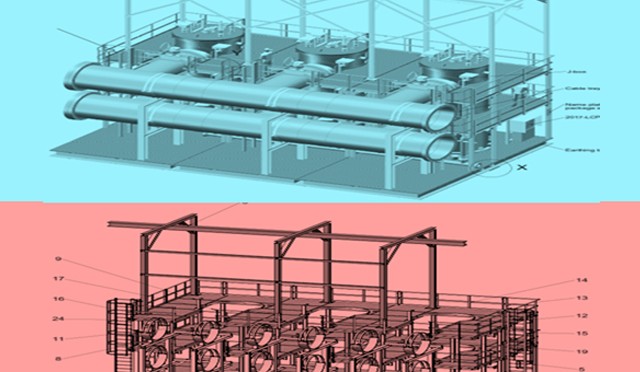

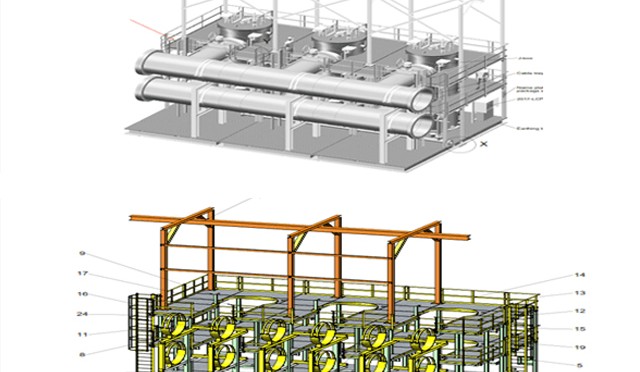

PIPE RACK MODULES FOR ZUBAIR OIL FIELD DEVELOPMENT PROJECT, BASRA, IRAQ

CLIENT

WEATHERFORD

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING,

ASSEMBLY AND PAINTING OF

3,900 METRIC TONS OF

PRE-ASSEMBLED PIPE RACKS

LENGTH: 24 M

HEIGHT: 5.6 M

WIDTH: 4.7 M

QTY : 112 NOS

EXECUTION TIME PERIOD:

8 MONTHS

66 FPSO HULL ECX-001, OFF SHORE MARINE PROJECT, RIO, BRAZIL

CLIENT

ECOVIX PETROBRAS – BRAZIL

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING,

TRIAL ASSEMBLY

AND PAINTING OF 1500TONS

MARINE PIPE RACKS

EXECUTION TIME PERIOD:

4 MONTHS

STAINLESS STEEL PRESSURE VESSELS FOR ASAB FFD PROJECT

CLIENT

PETRONASH/PETROFAC

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION,

TESTING,

PICKLING & PASSIVTION

LENGTH: 5.6M

DIAMETER: 2.6M

WEIGHT: 3.5 TONS

EXECUTION TIME PERIOD:

8 MONTHS

PEG ENGINEERING / WEATHERFORD / ENI / SOUTH OIL COMPANY

CLIENT

CLOSED DRAIN PRESSURE VESSELS FOR CRUDE OIL SEPARATION PACKAGES, ZUBAIR OIL FIELD DEVELOPMENT, IRAQ

SCOPE:

MECH DESIGN, FAB DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING, PAINTING

SHELL THK: 12MM

LENGTH: 8300 MM

DIAMETER: 2300 MM

WEIGHT: 14 TON

EXECUTION TIME PERIOD:

10 WEEKS

U-STAMP TEST SEPARATOR FOR WELL HEAD PLATFORM PROJECT, ZHDANOV-B PROJECT

CLIENT

ILK CONSTRUCTION / DRAGON OIL

SCOPE:

MECH DESIGN, ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION,

TESTING, PAINTING

THICKNESS: 50MM SHELL

TEST PRESSURE : 99.5 BAR

LENGTH: 5000 MM

DIAMETER: 1700 MM

WEIGHT: 20 TON

EXECUTION TIME PERIOD:

12 WEEKS

CHEMICAL INJECTION SKIDS – CORROSION INHIBITOR & ANTIFOAM FOR SOUTH PARS GAS FIELD DEVELOPMENT PROJECT, PHASE-14 OFFSHORE PLATFORMS

CLIENT

LEWA MIDDLE EAST

SCOPE:

ENGINEERING DRAWINGS,

MATERIAL PROCUREMENT, FABRICATION, TESTING, ASSEMBLY , PAINTING, F.A.T.

EXECUTION TIME PERIOD:

7 MONTHS.

METERING SKIDS FOR UPSTREAM ONSHORE OILFIELD PROJECT – MIS OILFIELD DEVELOPMENT IRAN

CLIENT

FMC TECHNOLOGIES

SCOPE:

ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION, TESTING, PAINTING , FAT.

EXECUTION TIME PERIOD:

4 MONTHS

METERING SKIDS – AZADIGAN PROJECT – IRAN

CLIENT

FMC TECHNOLOGIES

SCOPE:

ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION, TESTING, PAINTING . FAT

EXECUTION TIME PERIOD:

5 MONTHS

CUSTODY TRANSFER METERING SKIDS FOR FMC KONGSBERG METERING AS/BW OFFSHORE PAPA TERRA P-63 PROJECT, BRAZIL

CLIENT

FMC/BW OFFSHORE/ PETROBRAS

SCOPE:

ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION, TESTING, PAINTING , FAT.

LENGTH: 12 Mtrs

WIDTH: 11 Mtrs

HEIGHT : 13 Mtrs

WEIGHT : 180 TON

EXECUTION TIME PERIOD:

9 MONTHS

DOZING SKIDS FOR PROCESS INTEGRATION SERVICE FOR RMP-2 PROJECT

CLIENT

ENTROPIE / VEOLIA WATER / DAELIM / PETRON

SCOPE:

ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION, TESTING, ASSEMBLY AND PAINTING

EXECUTION TIME PERIOD:

6 MONTHS

CRUDE OIL SEPARATOR SKID PACKAGES FOR DEMIR DAGH EARLY PRODUCTION FACILITY, NORTHERN KURDISTAN

CLIENT

EXPRO / ORIX PETROLEUM

SCOPE:

1st STAGE & 2nd STAGE SEPARATORS

DETAILED ENGINEERING, MATERIAL PROCUREMENT, FABRICATION, TESTING, ASSEMBLY, PAINTING , BELZONA COATING, INSULATION, ELECTRICAL & FAT.

EXECUTION TIME PERIOD:

5 MONTHS

RUN DOWN COOLERS AND ASSOCIATED STRUCTURE AND PIPING FOR RAFIDIYA OIL FIELD DEVELOPMENT PROJECT, IRAQ

CLIENT

ENI IRAQ BV / SOUTH OIL CO.

SCOPE:

MATERIAL PROCUREMENT, SHOP FABRICATION, TESTING, PAINTING OF STRUCTURE & PIPING AND ASSEMBLY OF SKID PACKAGES AND COOLERS

EXECUTION TIME PERIOD:

7 MONTHS

ASSEMBLY OF SKID PACKAGES WITH PIPING FOR CRUDE OIL SEPARATION PROJECT, ZUBAIR OIL FIELD DEVELOPMENT PROJECT, IRAQ

CLIENT

ENI IRAQ BV / SOUTH OIL CO.

SCOPE:

DESIGN OF VESSELS , ENGINEERING DRAWINGS, MATERIAL PROCUREMENT, FABRICATION, TESTING, PAINTING, ASSEMBLY & FAT.

EXECUTION TIME PERIOD:

7 MONTHS